| |

HOME

|

| |

ACID AND METALLIFEROUS MINE DRAINAGE

|

| |

MINERALS PROCESSING

|

| |

CONTACT

|

|

|

|

|

|

| ACID AND METALLIFEROUS MINE DRAINAGE |

Mineralogy, Geochemistry and Surface Chemical Control of Acid and Metalliferous Drainage from Mine Wastes

|

| THE PROBLEM |

| The responsible management of acidic and metalliferous drainage (AMD) from mine wastes (as waste rock, process tailings, etc.) and in water release, is central to the social license to operate mining companies have with government and with communities adjacent to, and downstream from, the mine sites. The high economic, social, and environmental costs of AMD management failures in pre-planning and during operation are now recognized by the major global companies. The mining industry now includes AMD control as a top priority in greenfield mine planning, operating, processing, and in planning for closure. |

| A NEW APPROACH |

| Blue Minerals Consultancy (BMC) provides advanced assessment, new methods, new site strategies and advice to site consultants and environmental managers to minimise AMD release and management costs from more than 20 years research and development with 20 mining companies, AMIRA International and site consultants. The BMC approach to this minimisation is based on more complete analysis and interpretation of geochemistry, mineralogy and methods for control of surface reactions with protective layer formation. |

| PRINCIPLES |

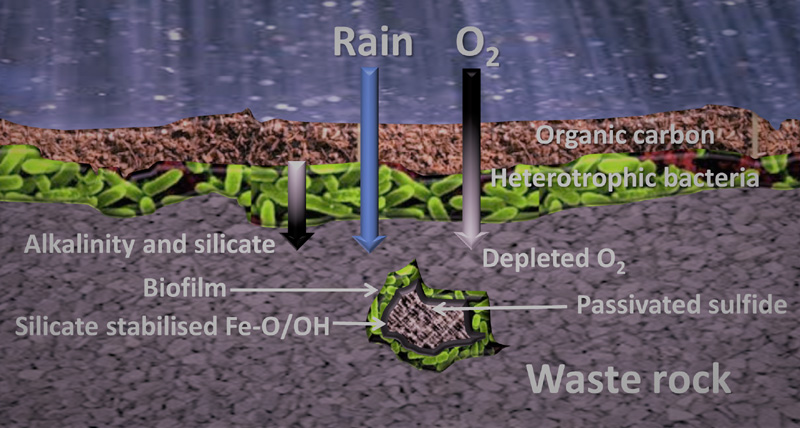

AMD management involves strategies, at any level from molecular to site storage scales, to minimise the interaction of reactive sulfide surfaces with air and/or water and to provide sufficient acid-neutralising material to match the acid generation. The matching of acid and neutralisation rates in kinetically controlled processes forms the basis for our innovative alternative to current practice. The BMC approach to sustainable AMD management in pre-planning or in operation is to use, where possible, geochemical resources available at the mine site to sufficiently reduce the acid generation rate (AGR) so that the acid neutralisation rate (ANR) (using site materials) can match the AGR in rock and tailings disposal before final rehabilitation.

The potential availability of on-site lithologies that can provide long-term neutralisation (ANR) is usually not gained from current geochemical assessments based on value. Detailed mineralogy is required, additional to standard AMD classification testing, of all site lithologies, preferably in greenfield assessment but also for operating and legacy sites. This allows a first-level estimate of ANR for different lithologies based on the mineralogy alone. This matching of acid and neutralisation rates in kinetically controlled processes is also, in principle, the only sustainable option for long-term closure. |

Schematic of dual barrier approach to acid mine drainage source control Schematic of dual barrier approach to acid mine drainage source control |

|

|

OUR ROLE

- BMC has developed initiatives, improvements and corrections in AMD assessment reducing required management costs including potential acidity reductions up to 80% in pyrite/pyrrhotite-containing wastes and more correct neutralisation potential using modified Sobek and mineralogy comparisons.

- The design and implementation of separate, advanced estimations of AGR and ANR, not only in the acid waste material, but also in identifying suitable neutralising mineralogy on site that may be available from materials not currently used in mined and processed wastes.

- Methods for passivation of pyrite and pyrrhotite oxidation in rock dumps and tailings reducing the AGR by more than 90%.

- Rapid assessment of ANR from both short-term carbonates and reactive silicates using methods alternative to long-term kinetic leach columns (with confirmation in kinetic leach columns if required).

- Determination of AGR/ANR ratio for estimation of approach to matching and any required additional neutralisation.

- Site testing in test pads, trial dumps, TSF treatments to verify planning.

- Advice to site consultants and environmental managers on options for dump and TSF design, remediation and management.

|

|